Besides the biting cold, living in snowy climates comes with its own benefits and the one that stands out the most is skiing. It is considered to be one of the most exciting hobbies and sports on earth and there are even special Winter Olympics that are held every four years just so people can go showcase their skiing skills. But for a beginner skier, you don’t wake up one day and decide to take up skiing out of the blue, you have to train hard for a while to get the basics right because it is a dangerous sport.

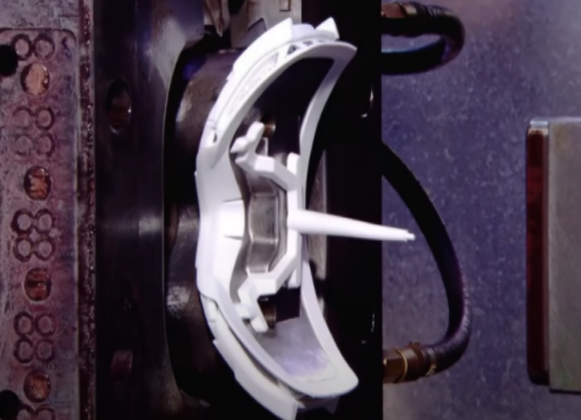

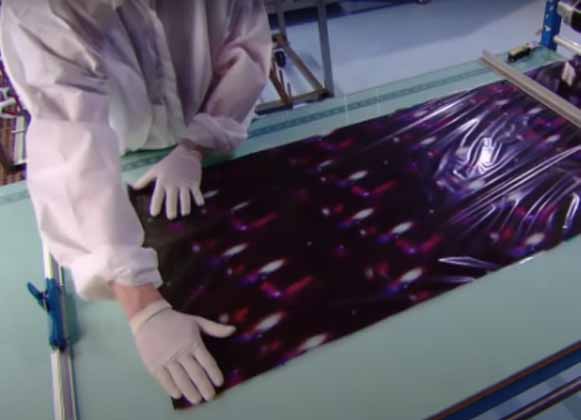

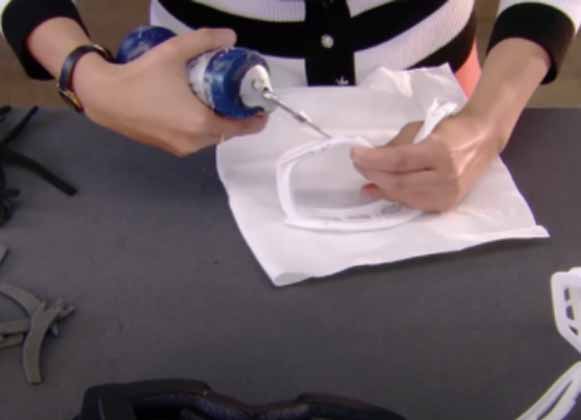

Most importantly, you need special gear to get that done. From skiing shoes and blades, to warm clothing, snow helmets, and most importantly, snow goggles. We will be exploring snow goggles, the different parts that make them work, the assembly techniques that snow goggle manufacturers use, and the things you have to factor in when shopping for them. So if taking up skiing has been on your bucket list, this is the article for you.